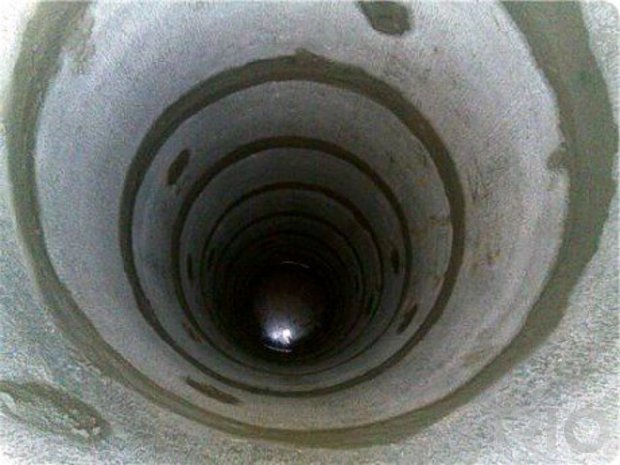

Wells are a source of drinking water. They are also associated with the arrangement of sewers. In both cases, high-quality waterproofing of the well is required. It is performed using various special mixtures, compositions.

Wells can be subdivided depending on the functions they perform:

- ordinary, their walls are destroyed over time under the influence of groundwater, due to which sand particles, chemicals, oil products, sewage, etc., can get inside, after which the water becomes polluted and can no longer be considered drinking water;

- septic tanks, the contents of which should not enter the groundwater, no sewage system is built without them;

- technical (they contain taps, pipes, branchings, etc.), where there should be no water so that the entire structure remains serviceable and a minimum level of humidity is maintained inside.

Features of waterproofing

When wells have been in operation for a long time, cracks can form in its walls. Moisture begins to penetrate through them. Water can also seep through the joints between the rings.

To avoid such problems, it is necessary to perform high-quality waterproofing of wells, which involves the following technological processes:

- finishing of seams formed by adjacent rings;

- processing of microcracks and all surfaces of rings.

Well insulation includes two types of work:

- external (labor-intensive, but effective);

- internal.

First, the joints and seams are sealed. To ensure the construction of a long service life, it is necessary to waterproof the wells from the inside, as well as from the outside. To avoid the penetration of water through the joints, it is recommended to use modern compositions and mixtures. If constantly incoming water interferes with the work, then it should be drained or pumped out.

You can prepare the mixture yourself by mixing PVA glue with cement. The composition must have such a concentration that it is well taken with a spatula. For the first layer, it is more convenient to use a liquid mixture that is easy to apply with a brush. Waterproofing the seams of the well can be done with geotextiles, which are very tightly plugged joints. And on top they are covered with liquid glass.

The surface of the rings becomes loose where water seeps through. This layer of concrete must be carefully removed and the wall cleaned with an iron brush. Inter-ring seams and places around the junction of communications should be punched and cleaned. It is also required to prepare the surface conjugated with the seam to a width of up to 150 mm. If as a result the reinforcement is exposed, then it is necessary to evaluate it. If rust appears, then it must be removed, and the metal should be treated with an anti-corrosion mixture.

When waterproofing a well is carried out in order to eliminate a pressure leak, a cement mortar (or a special composition) is used. Sealing of joints is carried out after wetting the concrete surface with water. It fits tightly with a spatula into strobes no more than 30 mm thick (or make several passes). You can reduce the consumption of the composition by adding fine crushed stone to the mixture (up to 50% of the total volume of the solution). Waterproofing of wells in wet soils is carried out 0.5 m above the calculated level of passage of upstream waters, taking into account their capillary rise.

Water filtration through walls can be prevented by treating the ring with a protective composition in 2 layers (the specific number is indicated by the manufacturer on the package). First, the surface must be cleaned and moistened (it is best to use a sprayer). Then apply the composition with a brush or using a mortar pump. The second layer is superimposed on a slightly set and moistened first.

The waterproofing layer is finally formed in 3 days. During this time, the surface must not be subjected to mechanical damage, as well as low temperatures. First (for 2 weeks) the waterproofing should be constantly moistened to prevent cracking. To prevent evaporation of moisture, the container must be covered with a special film. After the sealing of the seams in the well is completed, it is necessary to analyze the water and make sure that it is clean and not hazardous to health.

Waterproofing of septic tanks

When arranging sewer wells, reinforced concrete rings are used, which are laid to the required depth. In septic tanks, high-quality waterproofing does not allow drains to seep into the ground. Sealing prevents groundwater from entering the tank.

It is necessary to ensure that the waterproofing of sewer wells guarantees the absolute tightness of the structure (when the volume of wastewater exceeds 1m³). If the capacity is smaller, then it is possible to equip a septic tank, from which sewage enters the ground through the filter bottom.

When drains contain detergents or other chemical compounds, it is allowed to build exclusively hermetic structures.

If a well with drinking water is located on the plots, then it is recommended that the option of sewer wells with a filtering bottom not be considered at all.

The entire surface from the inside must be covered with some kind of sealed composition. Today there are the following materials:

- dry;

- containing epoxy resins resistant to aggressive compounds (gasoline, chemicals);

- liquid two-component.

Outdoor waterproofing

Reliable external waterproofing of the well prevents the negative impact of groundwater on the walls of the structure. It is more convenient to carry out such work during the construction of the well.

![]()

If an existing water source is being repaired, then soil is excavated around it 3-4 m deep. Next, the following work is carried out:

- loose concrete is removed;

- the surface of the walls is cleaned of everything superfluous (dirt, salt deposits, mold, moss, etc.);

- rust is removed from the bare fittings, the metal is coated with an anti-corrosion agent.

External waterproofing of the well can be performed using the following materials:

- rolled (roofing material) are superimposed on special mastics;

- cement mortar, with which damage is repaired, and a blind area is constructed;

- penetrating compounds;

- waterproof expanding (or non-shrinking) cement, which is used for shotcrete.

When sealing with roll materials, the following actions are performed:

- to ensure the desired adhesion, a primer is applied, 3 layers of bitumen-gasoline mixture can be applied (for this, a cement gun or a sprayer is used);

- after drying, the walls are repaired (damages are repaired), cement mortar can be used for this, but it is better to mix it with PVA;

- the patches dry out;

- the surface is primed again;

- the walls are covered with a coating material (tar or bituminous mastic), 3-4 layers of a waterproofing agent are applied on top;

- seams are smeared with mastic.

If impregnation is used, then a number of operations are performed:

- the moistened surface of the walls is lubricated with a deep penetration mixture;

- later, the impregnation is applied a second time;

- after 72 hours the layer dries up so that the surface does not crack, it should be moistened.

Sealing of sewer wells is performed in a similar way.

When shotcreting the walls of the well, the following sequence of actions is performed:

- a layer of cement (thickness 5-7 mm) is applied using a gun;

- after 10-12 days the solution will seize;

- the coating must be moistened so that it cracks;

- the 2nd layer is applied.

External waterproofing of the well is carried out to the very top. The space around the tank is filled with sand mixed with gravel and compacted. A cement pavement is made from above. It is recommended to equip a clay "castle" around the structure, which removes precipitation.

When arranging the container around the rings, a trench (about 50 cm wide) should be left, which must later be filled with clay. A slope must be formed above the ground so that precipitation flows off the structure. The upper rings hold back high groundwater. The above-ground layer protects the container from precipitation.

Waterproofing from the inside

For carrying out internal waterproofing using a modern method, a special environmentally friendly complex is used, which does not affect the taste of drinking water. In this case, the following materials are used:

- two-component coating mixture;

- a solution consisting of cement and polymer modifiers, with which damage is repaired, it has good adhesion;

- cement instantly hardening composition, "hydraulic plug" for heavily leaking places.

Before performing waterproofing inside an existing well, it is necessary to pump water out of it. After that, you should identify the damaged areas and perform the following actions:

- walls are cleaned of loose concrete, moss and dirt;

- cracks are cut to a depth of 20-25 mm and processed with a metal brush;

- seams expand and deepen up to 25-30 mm;

- if water has flowed, then immediately it is necessary to close it with a “hydraulic plug”;

- cleaned cracks, seams are sealed with repair mortar;

- when the patches have set, a coating insulation is applied to the pre-moistened surface with a brush, which is diluted to the desired consistency in accordance with the instructions;

- the mixture is applied in 2 layers from the bottom up, the walls are smeared again after the first has dried, complete solidification occurs in a day.

If you properly waterproof the well, then it will serve faithfully for many years.