When choosing devices for the heating system of a private house or apartment, owners often find themselves in a dead end and get lost when faced with a huge selection of devices. After all, correctly selected elements of the heating system are not only a guarantee of its long-term operation, but also maximum heat transfer.

Panel steel heating radiators are an invention of the late last century, which was promoted by the production of steel sheets, welding, painting in an attempt to create heating radiators that will have higher performance than cast iron batteries.

There is nothing complicated in the production of panel steel heating radiators. Initially, panels are stamped from 1.25 mm thick steel sheets. At the same time, U-shaped steel convectors 0.3-0.5 mm are manufactured. Already finished panels are welded by roller welding, and convectors are already welded to them. Painting takes place at the very end of the production of the product.

heating have hundreds or even thousands of items, require huge storage facilities that only large corporations can afford. In addition, the organization of a dealer and distribution network requires solid financial, material and human resources.

Advantages and disadvantages

Any product, regardless of its purpose, has advantages and disadvantages that are known in comparison. Steel radiators, in contrast, have a one-piece design, which can have a number of advantages over other panel types, but there are also disadvantages.

Advantages:

- Holistic battery design

After the purchase, the panel radiator is already completely ready for operation, and it only needs to be connected to the pipes. As in other radiators, you do not need to add or subtract sections. When buying, you should choose the desired panel size and that's it. The product only needs to be hung on the wall, and everything else, up to connecting to the pipes of the heating system, can be done later. Also, this advantage - integrity - becomes a disadvantage: in the event of a leak, you cannot replace only the section, as in other batteries, but you will have to change the entire panel.

- Aesthetics

Many say that the panel type of batteries is better than modern housing, but this is a matter of taste for everyone. If you paint the product to match the color of the room or curtains, then the panel radiator will become generally inconspicuous. Quite a few steel panel radiators come with a bottom type, which allows you to hide the pipes.

- High level of heat transfer

With a very high thermal conductivity, steel becomes an excellent material for choosing radiators with optimal technical characteristics. And the presence of convectors makes steel radiators for heating generally ideal in terms of heat transfer.

- Saving

Not everyone is suitable for a high-budget heating system for a private house, and in this case, steel panel radiators are a great solution. They keep a small amount of coolant in themselves, giving off its heat to the room as much as possible. Low inertia in conjunction with a radiator thermostat allows you to save up to 40% of energy.

Flaws:

- Corrosion resistant

In case of non-compliance with operating conditions, for example, work with low-quality coolant, steel panel radiators can quickly. The presence of air in the system, the pH value that does not correspond to the norm, the annual coolant drains - in this mode, the radiators will not last long.

- Low water hammer resistance

Water hammer does not occur in closed heating systems in private houses, but only in open - apartment networks. But for safety, if the batteries are installed in the apartment, it is worth securing the devices with some kind of extinguishing device. For example, a pressure reducer.

- Sensitive to transport

Any, even an insignificant steel panel, can lead to breakage and, as a result, leaks, which will lead to the complete unusability of the entire battery.

Performance characteristics and types

Basically panel radiators have the following specifications:

- operating pressure - up to 10 bar;

- test pressure - 13 bar;

- coolant temperature - up to 110 ° C.

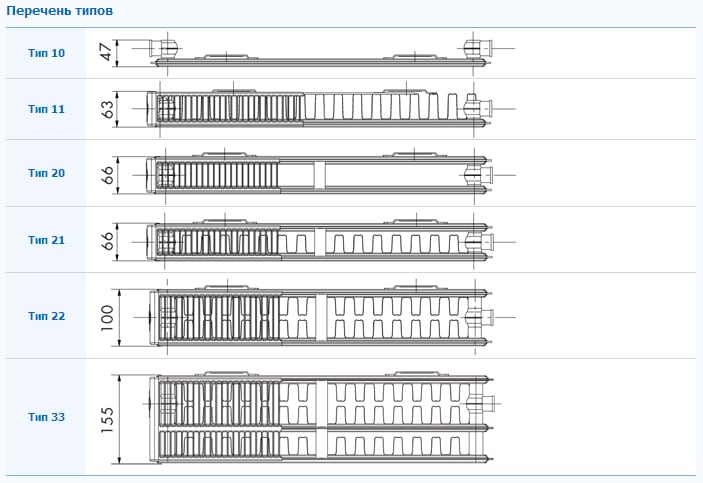

Panel radiators are divided into the following types:

- T 10 - single row, without convector and cladding;

- T 11 - single-row with one convector, without upper grate;

- T 20 - double row, without convector, with air outlet grille;

- T 21 - double-row, with one convector fin and with a closed casing;

- T 22 - double-row with two convector fins and a closed casing;

- T 30 - three-row, without a convector, closed with a grate from above;

- T 33 - three-row with three convectors and a closed casing.

Types 10 and 11, having no convection, are capable of heat transfer solely by heating the air.

Flat or stamped panels, having dimensions in height - 200-900 mm, in length - 400-3000 mm.

Vogel Nuth are the only manufacturers of vertical heating products with a width of 500-600 mm and a height of up to 2.6 m, types 10, 20K.

There are two types: side and bottom, with preset thermostatic valve.

Main differences between types 11, 22 and 33

A convector is a steel "coil" located between the panels of the heating device, designed to ensure that the air heated by the heating radiator, passing through the channels, has time to warm up.

The warmer the air, the easier it is. Its exit speed from the radiator increases, and if you bring your hand from above to a properly made radiator, you will feel the movement of air, as if a fan is driving it from inside. For example, battery Type 22 has two convectors.

According to international standards, the designation of the type of heating device (for example, Type 22) is its technical characteristics: the first digit is the number of steel panels, and the second is the number of convectors. Type 11 has one panel and one convector, Type 22 has two panels and two convectors, and Type 33 has three panels and three convectors, respectively.

Type 22 with two panels and two convectors, fins and a closed casing is the most popular and sold out. Since Type 22 is perceived by the consumer as a golden mean and with an optimal level of price / quality ratio.

There are also models VK 11, VK 22, VK 33, which differ in product thickness and power, but by name they correspond to the decoding of types 11, 22 and 33.

Proper operation and selection of the battery for the appropriate heating system will help the device last longer.