In order for the house to always be warm, the heating worked without failures and was distinguished by a low price, it is necessary to choose the right heat source and radiators. It depends on them how efficient the operation of the entire system will be. Today on the Russian market you can see a very large assortment of various heating devices. Among such an abundance, bimetallic radiators can be called the most profitable.

Any bimetallic heating radiator is made of two main elements:

- metal pipes;

- aluminum panels.

Due to this combination of components, a very efficient heat transfer occurs. The hot coolant moves along a steel core made of metal pipes. The aluminum shell heats up quickly and warms the air in the room.

Due to this combination of components, a very efficient heat transfer occurs. The hot coolant moves along a steel core made of metal pipes. The aluminum shell heats up quickly and warms the air in the room.

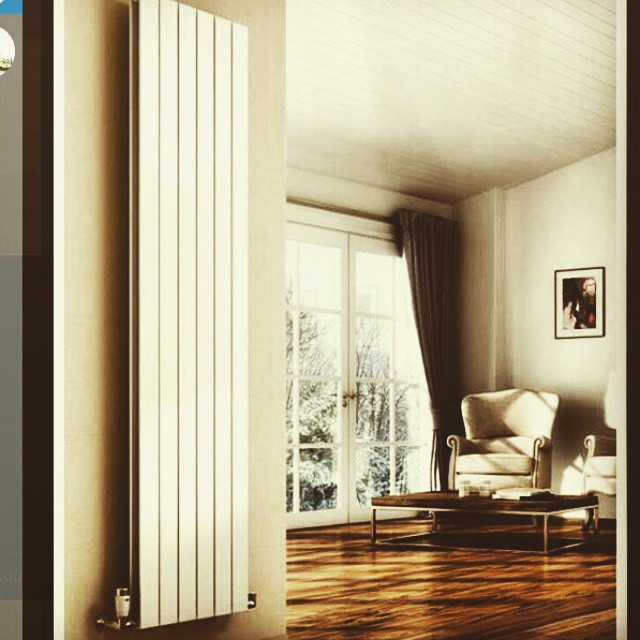

The figured aluminum shell of such a core has a beautiful appearance. It plays an important role in the even distribution of heat.

Thanks to aluminum panels, the radiator turns out to be quite light if we compare its weight with similar cast-iron batteries. Light weight greatly simplifies installation work. The original shape of the body always attracts the eye. A bimetallic radiator, in addition to a stylish look, increases heat transfer many times over.

The metal pipes from which the core is made are characterized by increased strength. They can freely withstand a pressure of 40 atmospheres. The coolant temperature that such pipes can freely withstand can exceed 130 degrees.

Each device is accompanied by a passport, which indicates the limiting parameters of the coolant temperature and maximum pressure.

What is better monolith or section?

When choosing bimetallic equipment for your heating, you need to think about the design of the radiator itself. It has several varieties:

- Sectional;

- Monolithic.

Comparative characteristics of such devices can be seen in the table below:

Manufacturers accompany their products with a variety of technical materials. They include instruction manual, user manual and product catalogs. In the tables presented, you can determine how many sections are needed to heat a room of a certain area.

Sectional systems with their performance characteristics are significantly inferior to monolith bimetallic radiators. Leaks can form at the joints of the sections.

Sectional systems with their performance characteristics are significantly inferior to monolith bimetallic radiators. Leaks can form at the joints of the sections.

The main disadvantage of monolithic structures can be called their cost. It is much higher than the price of sectional devices.

Monolithic bimetallic radiators must be installed in multi-storey buildings. The fact is that the coolant is always supplied under very high pressure. Only monolithic structures can freely withstand it.

Comparison of bimetallic radiators

Each owner, creating a heating system in his house, always tries to choose a product that has the most optimal technical parameters and the best performance characteristics.

To compare bimetallic radiators, consider their technical characteristics.

First of all, they must have the same size.

All directories indicate the parameters of only one section, but this is not enough for comparison. Therefore, it is necessary to compare not the devices themselves, but only the structural parts.

The main parameter of any battery is its center distance. It is measured between the axis of the upper and lower manifold. Today, models are mainly manufactured, in which the center distance is in the range: 200 - 800 mm.

Devices with a large center distance are usually produced with a greatly increased section height. However, the width of the radiator is much smaller. Such structures are quite rare. They are used only when the interior of the room is so small that it makes it impossible to install a horizontal radiator.

Dimensions of bimetallic radiators

The most important geometric parameters of the device are:

- Width;

- Height;

- Section depth.

Usually the height is greater than the center distance by 60 - 80 mm. Mostly, factories produce devices in which the section width is not more than 80 mm. The total width of the radiator is determined by the number of sections.

The depth is in the range of 80 - 100 mm. This dimension may be constant, or it may vary in height. A striking representative of this design is a beautiful device from the company "Royal Thermo" from the "Dream Liner" series.

Appliance power

Depending on the value of this parameter, the number of battery sections is determined so that a specific area can be heated.

Section capacity

The coolant circulates through metal cores. This is an H-shaped system with two collectors connected by a vertical pipe. The sections are connected with steel nipples. This design does not allow aluminum to come into contact with the coolant.

The cores of bimetallic devices are made of round tubes, which make it possible to reduce the capacitance of the section. For example, in the Rifar Base 500 model, the capacity reaches 0.20 liters, and in a conventional aluminum radiator of the Rifar Alum 500 type, with the same size, the capacity reaches 0.27 liters.

Section weight

Bimetallic heating radiators are distinguished by a greater mass in comparison with aluminum ones. This is due to the use of metal cores. The density of metal is always higher than that of aluminum. Therefore, the mass is more.

Bimetallic heating radiators are distinguished by a greater mass in comparison with aluminum ones. This is due to the use of metal cores. The density of metal is always higher than that of aluminum. Therefore, the mass is more.

For example, if we take a bimetallic radiator, brand "Varmega Bimega 500/80", its weight reaches 1.75 kg. An aluminum battery, model "Almega 500/80" produced by the same manufacturer, weighs only 1.2 kg.

Pressure

Bimetallic devices freely withstand pressure in the range of 16 - 40 atmospheres. When the system is tested, the pressure is applied 1.5 times higher than the working one. No leaks are allowed. The passport of the device indicates the maximum pressure that can be in the system. If the parameter is higher, the device may be destroyed.

How to calculate the number of sections

In the instructions attached to the device, its power must be indicated. Based on this value, the number of sections is calculated.

The main indicators are calculated by the formula: A = B x 100/C.

- A is the number of required sections.

- B is the area of the heated room.

- B - thermal power.

For example, we need to heat a room with an area of 12 square meters. meters, and the height of the ceiling reaches - 3.5 m.

We calculate the power of one section using the formula. As a result

A \u003d 12 x 100/200 \u003d 6 sections.

Sometimes when calculating, the final number is not an integer. Rounding is performed towards the larger number. Manufacturers produce bimetallic batteries of various sizes, so it will not be difficult to create a combination of them.

Manufacturers

When any product is purchased, it is very important to know where it was made, which company produced it. After all, branded goods are always better than ordinary ones. This also applies to bimetallic devices.

There are many different devices on the Russian market today. Among them, the most recognized and popular are:

Italian radiators

The engineers of the Italian company "Sira" came up with the design of a bimetallic radiator. Today, several models can be purchased on the construction market:

The engineers of the Italian company "Sira" came up with the design of a bimetallic radiator. Today, several models can be purchased on the construction market:

- "Radena";

- Global Style.

The appearance of such Italian devices differs from analogues in its attractiveness and originality. Radiators are compact, have a high-quality finish, interesting design. They are designed for a long service life. One section can be purchased within 1500 rubles.

Russian appliances

The most popular brand remains "Rifar". The quality of these devices is not lower than Italian models. However, their cost is almost three times less. One section can be bought within 500 rubles.

South Korea

Bimetallic radiators are manufactured by MARS. The devices have a copper core. Each section is sold on the market for 400 rubles.

Polish models

The REGULUS-system company is engaged in the production of radiators. As in Korean radiators, the core is made of copper tubes. The company gives a 25-year warranty on its products, with proper operation of the radiator.

China

Chinese bimetallic radiators do not have a beautiful decor, they do not have a beautiful appearance. However, the cost of such models is an order of magnitude less than similar products.