Modern homes are increasingly equipped with underfloor heating. After all, the availability of this method of heating increases with a constant high efficiency. Despite the simplicity of the very design of underfloor heating, they can be called the best option for heating a house or its additional.

Underfloor heating in its design can be of two main types: water and electric. Consider how an electric underfloor heating works and connects.

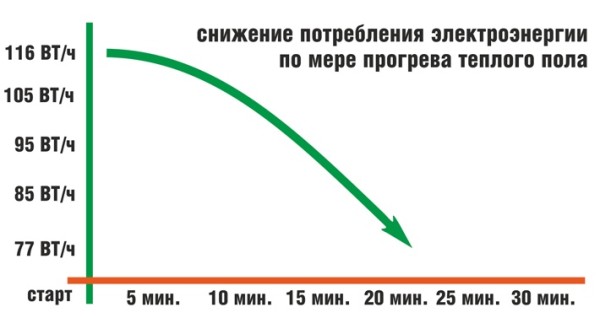

The principle of operation of warm electric floors simple: they convert electrical energy into thermal energy due to the resistance of conductors. At the same time, the screed or tile warms up. It is these materials that are able to evenly distribute heat over the entire area and give it to the environment.

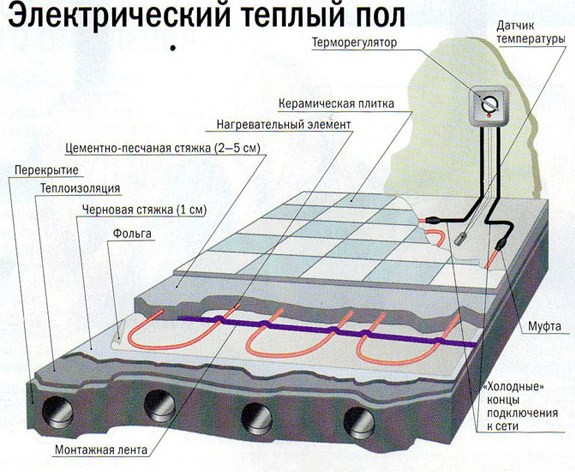

Underfloor heating powered by electricity has a fairly simple design and consists of the following main parts:

- heating element (depending on the type, it may be a cable or a mat);

- temperature sensor;

- thermostat.

Many people think that it is difficult to lay a warm floor and it is difficult to connect it to electricity. In fact, at its core, this type of underfloor heating resembles ordinary wiring, which is laid in layers of screed or under tiles. For full-fledged work, an ordinary socket is enough, where there is an alternating current with a voltage of 220 V.

The connection scheme itself does not cause any difficulties - this does not even require special knowledge. But be sure to remember during work that this is an electric current, which, if mishandled, can greatly harm a person, even death. To prevent this from happening, you must clearly follow a number of rules when choosing and connecting.

Selecting the power of a warm floor

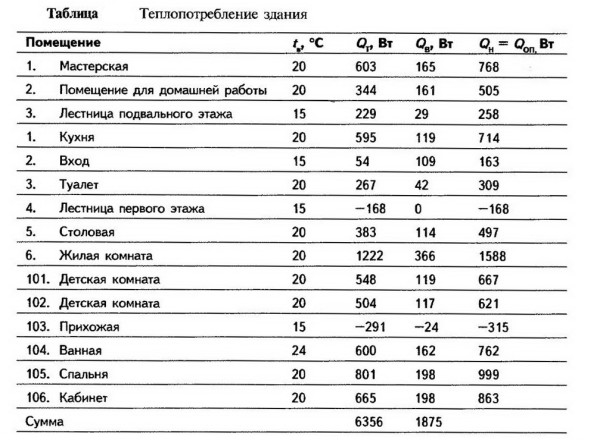

The most important indicator that you need to focus on when choosing underfloor heating is their power. This criterion depends on the following points:

- floor area to be heated;

- type of heating required (additional or main);

- type of room where heating will be carried out (balcony, living room, office, warehouse).

The type of connection to the network and the presence of additional elements depend on the power.

When carrying out calculations of a warm floor, you need to take only the usable area where a person is most often located. So, if this is a kitchen, then under the furniture and the refrigerator you can not calculate the area. When making calculations, it is imperative to determine in advance the location of all heating elements, since it will be impossible to change their positions in the future.

If you decide to use a warm floor as the main heating, then the area allocated for it should be at least 70% of the entire room.

Specific power of underfloor heating and its calculation

Warm floors can be used both as the main source of heat in the house, and as heating. For the first type, the calculation is taken approximately 150-170 W per 1 sq.m. Heating is calculated based on the values of 110-130 W per 1 sq.m.

This indicator may vary slightly depending on the type of heated room. For example, rooms where people are constantly occupied must necessarily have very warm floors, and for this reason the calculated power consumption is increased. If this is a kitchen or bathroom, then here you can not overestimate the values \u200b\u200bbecause residents spend little time in them.

Types of electric underfloor heating and thermostats

Now there are two types of electric underfloor heating:

- cable or sectional;

- mats, infrared film systems.

Each of these types has its own characteristics and is used in specific cases. So, if a warm floor is mounted in a concrete screed, then it is better to use a cable type. Mats or film heating elements are best suited for tiles.

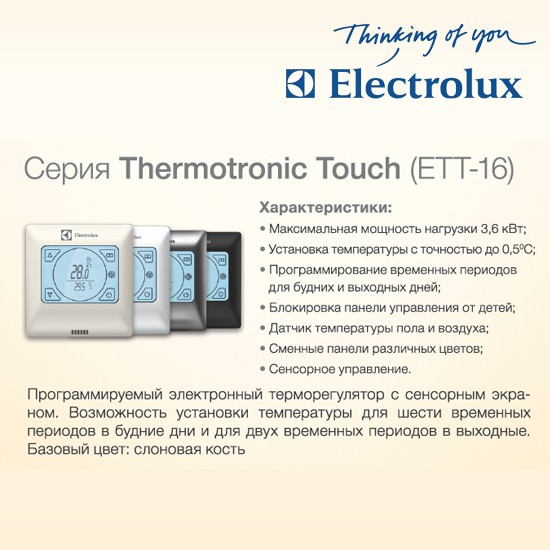

Naturally, the main part of the warm floor is itself heating element. But it fully works thanks to thermostat, which is the heart of the system.

It allows you to maintain the desired surface temperature. Buying a thermostat is not a problem: it can be either mechanical, with manual setting and temperature control, or fully automatic, with surface temperature measurement, indoor air temperature and selection of the most optimal parameters.

Connecting the thermostat to the system

Before connecting a warm floor, regardless of its type, you need to determine the location of the thermostat. This device is used to maintain a stable set temperature indoors. In addition, by means of a thermostat, a direct connection of a warm floor to the network is made.

The thermostat is installed at a height of at least 1.5 meters from the floor and in places where it will be completely protected from high temperatures. This will allow you to make measurements as accurately as possible and set the desired floor heating.

Before connecting the thermostat, you must first decide what method it will be done: powered from the shield or using an outlet. It should be noted right away that these two methods involve the additional inclusion of a circuit breaker in the circuit, which will operate in the event of breakdowns, overheating or short circuits. Its maximum shutdown power is selected depending on the type of underfloor heating.

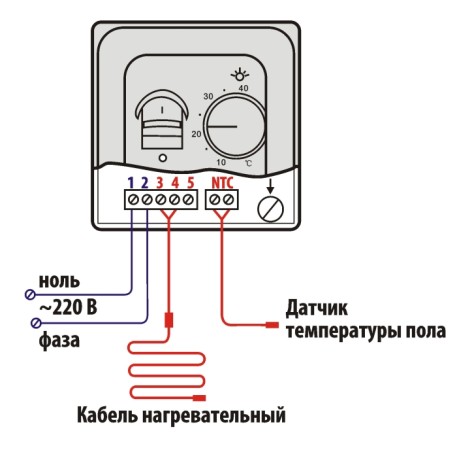

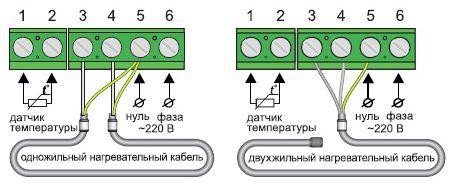

In most cases, the connection diagram is indicated on the thermostat, which greatly simplifies installation without the help of electricians. If there is no diagram, then the following wires must be connected to the following terminals:

- 1 terminal - network phase;

- 2 terminal - network zero;

- 3, 4 terminals - conductors of the heating element;

- 5 terminal - timer;

- 6, 7 terminals - floor temperature sensor.

This distribution is standard, but it should be understood that different manufacturers may create circuits that require a different connection. It all depends on the design and additional features of the system.

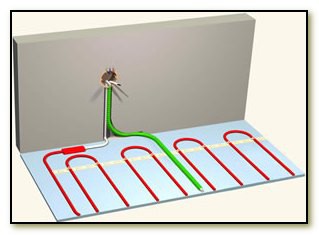

Before connecting, you need to cut a small ditch in the wall. It will house two plastic tubes. In the future, the wires of the heating element will be passed into one, and the temperature sensor will be located in the second. At the end of these activities, you can proceed with the installation and connection of the entire underfloor heating system.

Connecting a cable-type underfloor heating system

To connect a cable underfloor heating, you need to level the surface. Next, attach a damper tape along the wall and then lay the thermal insulation. Cable installation can also be carried out on an old surface, without lining. The only condition for this is the presence of a heated room from below. Before laying the cable, you need to stretch all the wires to connect to the thermostat.

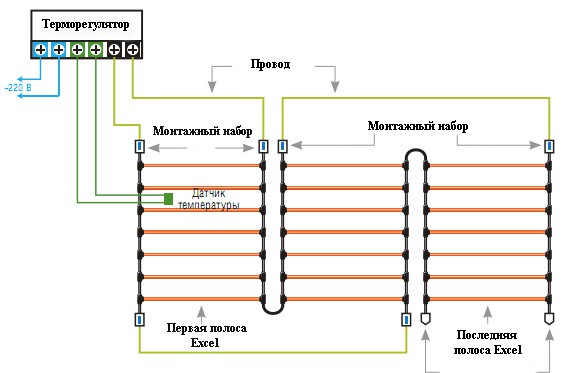

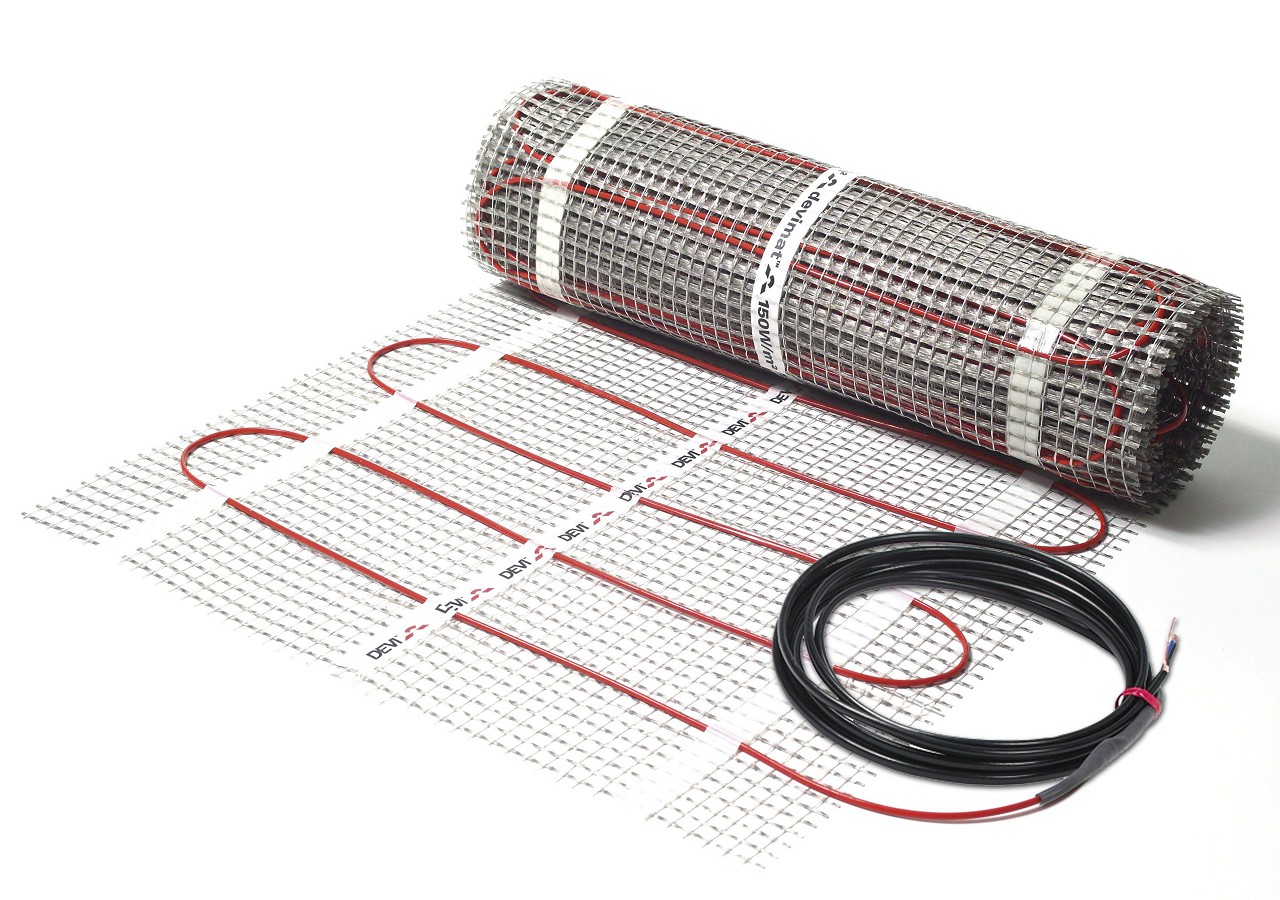

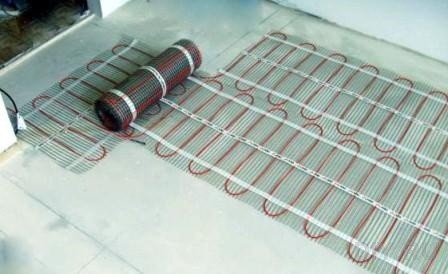

Next, you can lay the heating element, after placing the usual mounting tape on the floor. This is done so that the cable is held in the desired position and does not move. You can lay the cable in any shape, the main thing is that it does not intersect with itself. The most efficient and convenient installation method is the so-called "snake" - the cables are sold in rolls, already laid in the form of a coil on the grid.

Evenly distributing the cable, you can fix it. It is important that the edges do not reach the location of furniture or walls by about 10 cm. Next, you need to lay a temperature sensor, which is hidden in the tube mentioned earlier. Its location should be at a distance of 40-50 cm from the edge of the coil of the heating element.

This completes the installation of the cable and sensor. Using a tester, you need to check the resistance of the heating element. It must match the passport data. Next, you need to fill everything with a screed and wait until it hardens. It is impossible to immediately turn on the warm floor to dry it, as cracks will appear and the strength indicator will significantly decrease. It remains just to connect all the wires to the thermostat and check the system's performance.

Connecting a warm floor in mats

To figure out how to connect a warm floor in mats, you do not need to have a lot of knowledge and experience. The basic principle is about the same as that of the cable type. It is worth noting some differences.

A thermal mat is a heat-resistant film on which a heating element is attached. Since the pitch and shape of the laying is already set during production, you only need to calculate the area to be heated and the power consumption.

When installing such heating, it is necessary to lay out the mats on the surface, according to the calculated area. Then everything is poured with a thin concrete screed or glue is applied for laying tiles. A very important point is lack of thermal insulation. This can lead to overheating of the system and its failure.

If the length of the cold leads is not enough to connect, just a piece of mat is used. The coupling must be located inside the screed itself.

Connection to the electrical circuit of a film type underfloor heating

Underfloor heating film type is a relatively new invention. It is made of a special heating film. With the connection of this system, even the most experienced builders can have problems. In order to do this without problems, it is necessary to deal with the film floor heating system itself.

The film underfloor heating system consists of special carbon and bimetallic heating elements, which are soldered in a special heat-resistant material. Copper contacts are located along the edges of the film. They connect the device to the network.

The connection itself is carried out by soldering the wires to the terminals and leading them to the thermostat. A feature of laying is the use of a substrate that has a foil surface. This solution allows heat to be reflected from the lower surface and directed completely to floor heating.

The temperature sensor is installed, as a rule, in a special recess under the film itself, but options for its location on the surface are not excluded. Also, this type can be cut according to special marks that are applied by the manufacturer. They are located at a distance of up to 30 cm from each other. When the laying is done, you can connect the sheets in a parallel way.

The main difference of a film heat-insulated floor is that it approaches under any surfaces. The only exception is its installation under the carpet, as there is a high probability of damage to the integrity of the film.

The decision to make a warm floor in the house has always been justified. It is convenient, practical and quite economical. And if there are children in the house, a warm floor will allow parents not to worry that they will freeze and get sick.