A country house is a pleasant luxury, which is a considerable pleasure to afford. At least, therefore, it is worth carefully considering every detail. One of the interior elements that allow you to create comfort in the house has long been a fireplace. Its presence in the house not only decorates the room, but also allows you to warm up on long winter evenings. At the same time, often it is he who is the culprit of the fire. Most often due to an improper chimney device, without which the normal functioning of the fireplace is impossible.

You can build a chimney by resorting to the services of specialists. This, of course, will cost a pretty penny, but you will be sure of the result for sure. But for those who, for a second, do not doubt the skill of their hands and strive to achieve everything in this life on their own, we offer to build a chimney with our own hands.

The most important thing is to properly organize the system for removing combustion products in order to protect yourself from unnecessary troubles, as well as to optimally distribute the movement of warm air flows that heat the room.

In the event that the chimney is not installed properly, you risk running into the problem of smoke in the room, the smell of burning, the return draft of the fireplace, and even the spread of fire.

And yet, how to make a chimney with your own hands and not be mistaken? Let's try to figure it out.

A bit of history

In the 90s, brick chimneys gained particular popularity in the Russian chimney market. They were of high quality, beautiful and functional, and nothing more was required of them. The most difficult thing was to find a master who was ready to build such a structure correctly. Among the shortcomings of brick chimneys, which are sometimes relevant to this day, they note a non-insulated structure, due to which harmful condensate forms. Over time, it corrodes the brickwork of the chimney, and, accordingly, the chimney itself, and work can be started all over again. In addition, brick chimneys are quite heavy, and therefore need to build a special foundation. The construction of the foundation, and, moreover, a brick chimney, is a difficult and time-consuming process that must be carried out only at a positive temperature. If you want to make yourself a chimney of this type, then you need to think in advance about its location. In general, if you want to build a brick chimney with your own hands, get ready for great difficulties. But the problem with condensate was partially solved by the invention of insulated modern brick chimneys, but the construction of a brick structure still remains a complex, non-repairable and heavy process. Among other things, brick chimneys carry with them high financial costs, because of which many do not dare to make a choice in their favor.

Gradually, brick and ceramic chimneys began to leave the leading market positions, and a new type of stainless steel chimneys came in their place. Such chimneys are made of high-quality materials, do not contribute to the formation of condensate and are distinguished by unique properties that are inaccessible to their predecessors. And if ceramic chimneys can only be built together with the house, then the installation of a stainless steel chimney will work perfectly in an already finished building. The inner surface of the pipe of such a chimney has a perfectly smooth structure, which significantly increases its performance.

New generations of metal structures do not require foundation construction and special weather conditions for their installation. They are easily repaired at any time of the year. And, if the durability of ceramic and brick chimneys depends entirely on the professionalism of the master who carries out the laying out, then metal chimneys depend solely on the materials used for its manufacture.

The modern chimney market is represented by a number of leaders, such as double-wall stainless chimneys, single-wall stainless chimneys and coaxial ones.

- Double-wall stainless chimneys are great for boilers, fireplaces. Geysers and furnaces. They are the most common group, and in their design resemble a sandwich of an inner and outer pipe, between which there is a heater.

- The installation of single-walled chimneys makes sense if they are used for repairing or otherwise “sleeving” brick chimneys, as well as connecting them.

- It makes sense to buy a coaxial chimney to supply air to some types of boilers, as well as to remove smoke. They resemble double-walled devices, only their inner pipe is needed to remove combustion products, and the space between the pipes is necessary to supply air for combustion.

In Russia, one of the most famous representatives producing stainless steel chimneys is the Domotekhnika company with the Volcano chimney trademark.

Volcano chimneys are distinguished by a thick layer of fire-resistant insulation between the inner and outer pipes of 50 mm. The chimney manufacturer Vulkan uses ROCKWOOL basalt wool from Denmark as the basis of the insulation, which protects the pipes from condensation, cooling and improves the performance of the chimney. The inner wall is ustenitic stainless heat-resistant steel, which is corrosion-resistant, reliable in operation, stable in structure and resistant to environmental influences regardless of climatic conditions.

All these qualities distinguish Volcano chimneys from other companies. When choosing and buying a chimney, you should pay attention to the models of this manufacturer.

What you need to know when laying a chimney?

It is quite difficult to build a high-quality, reliable and functioning chimney on your own, since this business requires maximum attention and accuracy, because the further operation of the chimney, its durability and removal of combustion products will depend on these works.

The height of the chimney depends on the characteristics of the boiler, stove or fireplace you have chosen, as well as the diameter of the pipe.

In addition, the installation of a chimney requires such a previous stage as design. It assumes the fulfillment of a number of conditions:

- The pipe laid in the heated room is not insulated, but 60 cm before the location of the ceiling, a sandwich insulation device is installed. Existing building codes state that laying through uninsulated pipes is prohibited. At the same time, the channels that pass through heated attics must also be insulated, for example, with “sandwiches”.

- The height of the chimney (chimney) must not be less than 5 meters.

- The design and installation of chimneys involves the stage of selecting characteristics (for example, diameter, height and traction force) subject to the following condition: the higher the pipe, the higher its draft. It is necessary to observe the optimality of this ratio, because if the pipe section is small, then the system will “choke” with smoke, and if it is too large, the draft will decrease.

- An important condition: maintaining the harmony of geometric proportions between the height of the pipe, the ridge of the roof and other parts of the system (for example, the ventilation ducts of the house).

- Joints of structural elements should be placed below or above interfloor lintels, and should also be open for easy visual viewing. This will help you in the future with the operation of the chimney.

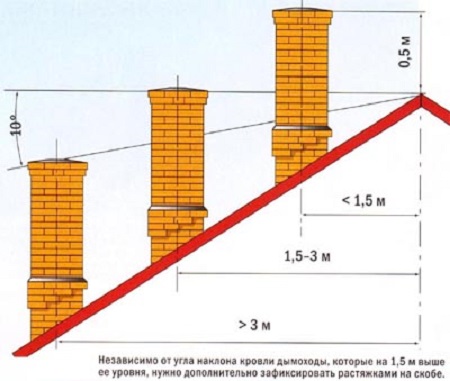

- At intervals of 1.5 - 2.5 meters along the entire length of the chimney pipe, it is necessary to fasten the pipe to the wall with clamps. Similar fastenings are made in the corner pipe bends. A pipe protruding more than 1.2 meters is fixed on the roof thanks to special stretch marks.

- When performing installation work, it is a mandatory requirement to comply with fire safety rules, which state that all wooden elements that are adjacent to the installation site and surfaces must be treated with special flame retardants, and their insulation with non-combustible materials will not be superfluous. Particular attention in this case requires the place where the "sandwich" is laid through the floors, and the place where they go to the roof.

Aesthetic side of the chimney

Installation of chimneys requires not only proper work, but also a preliminary selection of the appearance of your chimney.

The modern chimney market allows us not to dwell on the options familiar to us, but to choose such a beautiful appearance that would not only allow the device to function well, but also warm the soul. For example, you can diversify your chimney with special reflective screens and galvanized metal pipes, which will undoubtedly delight fans of high-tech style. The wall along which the chimney pipe is located can be lined indoors with unusual ceramic tiles with intricate patterns. The outer part of the chimney pipe is covered with galvanized iron to give a beautiful look and painted in your favorite color using enamels that are heat resistant to high temperatures.

The tip of the iceberg

The height of the chimney in any situation will depend on the configuration of the roof. In the case when the distance from the roof ridge to the pipe does not exceed 1.5 meters, the height of the chimney (pipe) must be at least 50 centimeters above the level of the ridge. If the distance of the pipe from the ridge does not exceed three meters, but more than 1.5, then the height of the chimney must be greater than or equal to the height of the ridge. With a distance of three meters, the height of the pipe is defined as a line drawn at an angle of 10 degrees to the horizon from the roof ridge. Above a flat roof, the height of the chimney usually rises by less than 120 centimeters.

If the pipe rises by more than 1.5 meters, it will be necessary to carry out additional pipe insulation using brackets and extensions.

The rules for the operation of heating appliances state that a reflector, a cone and a bend on the top of the chimney pipe are prohibited. It must remain open. Chimneys for gas boilers only in this case will function according to their characteristics.

DIY chimney. Installation

Most often in practice, a two-circuit design is used. For this simple reason, let's look at the installation process of just such a system.

Installation is carried out from the bottom of the structure to its top, that is, away from the heating objects in the room, directly to the chimney itself. In this case, each next pipe link is inserted into the segment preceding it, this makes it possible to provide protection for the structure from moisture ingress into it. For additional protection, a sealant with an operating temperature of about 1000 can be used.

Working joints are stuck together with special clamps, along the laying line, after 1.5-2 meters, brackets are installed to fix the pipe. Separate horizontal sections of the structure should not exceed 1 meter and should not touch nearby communication elements (gas pipes, electrical wiring, etc.).

A do-it-yourself chimney also requires that the working channels be placed along the walls of the building or internal partitions, manufactured and non-combustible materials. It is allowed to be located next to an insulated structure in the form of a pipe, with its special insulation.

Chimneys for gas boilers

Things are a little different in the area where you need to make not just a chimney with your own hands, but figure out how to do it for a gas boiler.

Such chimneys are divided into two types:

- Internal;

- External attachments.

The standard section is round, as a rule, with a chimney diameter of 130 mm. Most often, stainless steel is chosen as the material, because high temperatures and aggressive acid condensate act quite hard on the inner surface of the chimney. That is why chimneys for gas boilers are different from all the others. In some cases, owners prefer to use materials such as ceramic, heat-resistant glass or asbestos-cement pipe.

The installation of chimneys in this case depends on the design of the boiler. Do-it-yourself chimneys for gas boilers must be certified to the gas service. Otherwise, permission to operate a gas boiler will not be given. And for the operation of the boiler without permission, you face a large fine.

Chimney Care

A do-it-yourself chimney requires not only proper installation, but also subsequent maintenance.

To do this, it is enough to inspect twice a year (at the beginning and end of the heating period), checking the quality of traction, the integrity and tightness of the seams and joints of individual links, as well as periodically cleaning it from soot deposited on the inner walls.