Currently, pyrolysis boilers are quite widespread. This is due to the fact that as a result of two-stage combustion of solid fuel, its complete combustion occurs. This greatly increases the efficiency by almost 90-92%. What are these boilers? What does the pyrolysis boiler connection diagram look like? You can find answers to these questions in this article.

Pyrolysis boiler - what is it?

Pyrolysis boiler is a kind of solid fuel boilers. As a rule, this is the case. In this device, the combustion of solid fuel and the volatile substances that come out of it is carried out separately.

Fuel types

As fuel for pyrolysis boilers, you can use:

- Peat, fuel briquettes.

- Furniture waste.

- Waste from timber processing, sawdust.

- Various firewood: spruce, linden, pine, birch, alder, oak, etc.

- And many other types of solid fuels.

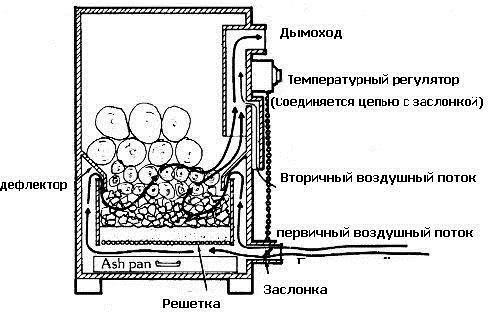

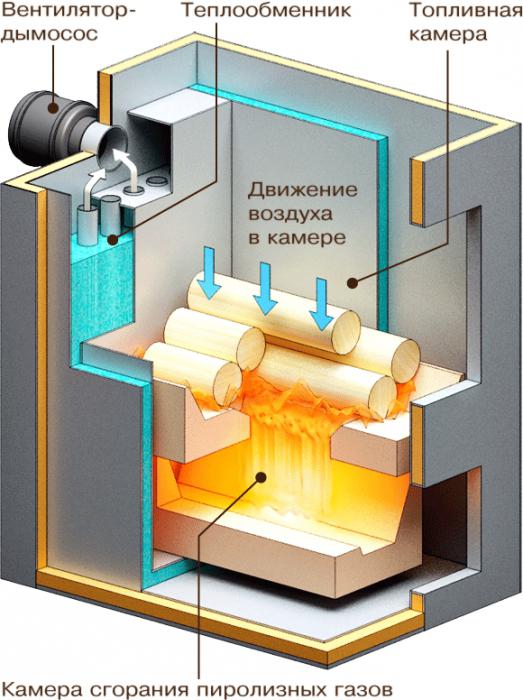

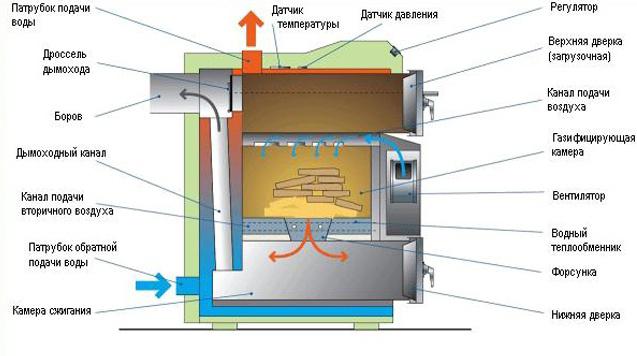

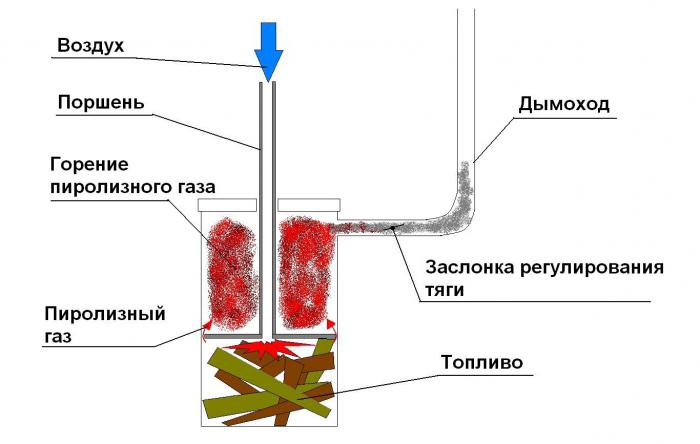

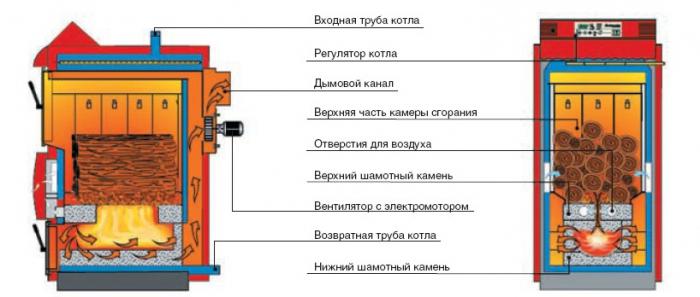

Operating principle

Before considering the diagrams and drawings of pyrolysis boilers, it is necessary to understand the principle of their operation. So, in the process of fuel combustion (in other words, dry distillation) under the influence of a high temperature regime (about 200-800 ° C) and an insufficient amount of oxygen, wood is decomposed into two parts: a volatile part (pyrolysis gas) and a solid precipitate

The scheme of the pyrolysis boiler assumes that pyrolysis gas will accumulate at the top of the chamber, which, with the air flow created by the smoke exhauster, will be sent for afterburning to another chamber. This is an exoteric process, accompanied by the release of heat, with the help of which heating is improved, the fuel is dried in the boiler, and the air entering the combustion zone is also heated. The mixing of the pyrolysis gas released at a high temperature with air oxygen causes the combustion process of the first, which is subsequently used to generate thermal energy.

Efficiency

How effective the pyrolysis boiler circuit will be, as well as its operating time, will depend on many factors:

- Fuel type and humidity.

- Thermal insulation of the building.

- Room temperature.

- Air temperature outside.

- Accuracy of design work in relation to the heating system.

Naturally, unlike conventional boilers, gas generating equipment is much more efficient. Since when burning wood it is impossible to obtain such high temperature indicators as in the process of burning wood gas obtained from it. The gas combustion process provides for the use of a smaller volume of air. In this regard, the burning time and temperature increase. It should also be noted that the control of the pyrolysis gas combustion process is much simpler.

Advantages

So, the scheme of the pyrolysis boiler has the following advantages:

Flaws

- Energy dependence - does not work well in the absence of a supercharger or smoke exhauster.

- Higher cost - about 1.5-2 times.

- At low loads (less than 50%), unstable combustion is noted, tar formation is possible in the gas ducts.

- Such devices are demanding on the moisture content of the fuel.

- The wood-burning scheme of the pyrolysis heating boiler excludes the organization of automatic fuel supply.

- To prevent low-temperature corrosion and condensation in the gas path, the return water temperature must be at least 60 °C (rarely 40 °C). However, this problem is solved by mixing direct water with return water.

- Compared to gas and electric devices, these boilers are much larger. This aspect must be taken into account when choosing an installation site.

Fuel used

It is necessary to use wood as fuel, the diameter of which is 100-250 mm, and the length is 380-450 mm. should be 30×300 mm in size. In the process of burning firewood, it is allowed to use small sawdust. However, they should be added no more than 30% of the total volume of the loading chamber. Only in this case, the scheme of a home-made pyrolysis boiler will be effective. In addition, these devices are capable of burning wet wood, but on condition that their moisture percentage is not more than 40.

To ensure the operation of such a boiler at maximum power, it is necessary to use only dry fuel. Since the ability of fuel to release energy is determined taking into account the presence of water in the wood.

Pyrolysis boiler assembly scheme

Before assembling this heating installation with your own hands, you need to familiarize yourself with the diagram. If you do not have any knowledge in this area, you do not need to try to do everything from scratch on your own. It is enough to take the finished drawing and make small adjustments to suit your own requirements. Get a diagram specifically for your equipment. In the specialized literature, you can find schematic diagrams and drawings of pyrolysis boilers.

Essential elements

For example, let's take the finished scheme of the Belyaev boiler with a power of 40 kW. It contains the following main elements:

Of course, having experience and some engineering knowledge, you can easily change the design of the boiler. The connection diagram of the pyrolysis boiler can be modified at your discretion. However, work must be done in such a way as not to violate the dimensions of the inner chamber.

Tools and materials

To mount such a unit on your own, you will need the following set of tools and materials:

- Thermal sensor.

- Fan.

- Strips of steel of various thicknesses and widths.

- A set of professional pipes with a diameter of 2 mm.

- Sheets metal 4 mm thick.

- A set of pipes of various diameters.

- with a diameter of 230 mm.

- Grinding wheel with a diameter of 125 mm.

- Manual (Bulgarian).

- Several packages of electrodes.

- Welding machine.

- Electric drill.

If you plan to make your own pyrolysis boiler, then the recommended steel thickness should be 4 mm. To save money, you can use steel 3 mm thick. For the manufacture of the body of the device, you will need durable steel that can withstand high temperatures.

Pyrolysis boiler - manufacturing scheme, main stages

To independently assemble a gas-generated heating unit, you must adhere to the following requirements:

An excellent option would be to share a pyrolysis boiler not with classic water heating, but with air heating systems. As a result, air will be transferred through pipelines and returned to the system through the floor. Such a system has numerous advantages: it does not freeze in severe frosts, there is no need to drain the coolant when the owner leaves.

- the unit must be carried out with the strictest observance of fire safety requirements. This device involves combustion processes that are characterized by high temperature indicators.

- The boiler room should be located in a separate non-residential premises.

- To maintain proper air ventilation, an opening of 100 cm 2 must be provided.

- The unit is mounted on a brick or concrete base.

- For the firebox, protection must be installed in front of the chambers. It is a metal sheet 2 mm thick.

This completes the independent installation of the pyrolysis boiler. As you have already noticed, there is nothing complicated in this. The main thing is that the detailed scheme of the pyrolysis boiler is correctly done. If you are not confident in your own abilities, then you should not tempt fate - contact the professionals.

User manual

Air supply can be done in two main ways: by the injection method or by the exhaust method (use of a smoke exhauster). The use of the injection option allows you to adjust the flow power, which allows you to control the intensity of combustion, the process of transition from smoldering to the issuance of maximum power in a short period of time.

As for smoke exhausters, today they produce such designs that can provide vacuum draft, capable of carrying out the pyrolysis process without heat loss.

The most economical mode of operation of the boiler is when the water is heated up to 60 °C. If all conditions are met, then this temperature is reached after 30-40 minutes.

The normal functioning of the heating system directly depends on the moisture content of the wood. It is not recommended to use firewood with a moisture content higher than 50%. The most optimal is the moisture content of firewood, equal to 25-30%. In order to achieve such a percentage of humidity, it is necessary to dry the firewood for a long time on ventilated areas, in special woodsheds, sheds (depending on the initial humidity and wood species).

When using firewood with a moisture content of 15-20%, compared to 50% moisture, the power increases by about 2 times. However, in natural conditions it is quite difficult to obtain such humidity. It will take approximately 1.5-2 years. Therefore, immediately after the end of the heating season, it is necessary to start harvesting firewood.