Gas is the most economical fuel. However, it should be noted that the arrangement of centralized gas heating is not always feasible. A worthy alternative to gas fuel is compressed biofuel from wood - pellets.

Pellet heating boilers - safe, environmentally friendly and cost-effective heat supply for a country house, cottage or small country house.

The device and principle of operation of pellet heating boilers

Pellet boiler - a device that runs on a special solid fuel - pellets. The pellets are made from wood waste (shavings, sawdust, straw, sunflower and buckwheat husks) by pressing. Fuel pellets are produced in sizes: diameter - 5-10 mm, length - up to 7 cm. When burning 1 kg of pellets, it releases 4500 Kcal - this is enough for heating rooms of various sizes.

Modern pellet boilers are equipped with an automatic fuel loading system - this increases the battery life of the boiler up to several weeks.

Pellet boilers are composed of three different mechanisms, combined into a single functional device. Usually, this is the boiler itself, equipped with a pellet burner, a pellet storage bin and a mechanism for supplying fuel to the combustion chamber.

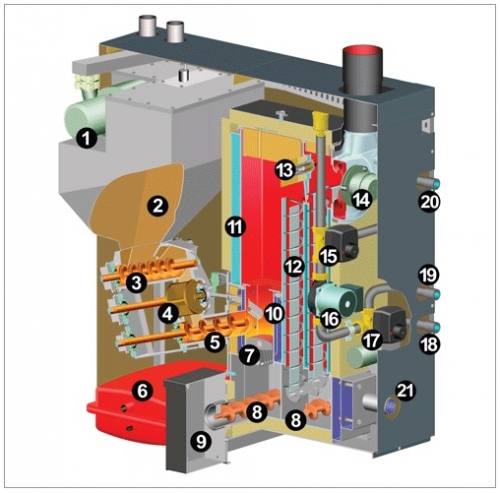

The design of the pellet boiler

Designations in the figure:

1 - turbine sucking pellets;

2 - container for pellets;

3 - screw metering the fuel supply;

4 - rotary valve;

5 - furnace screw;

7 - grate with brushes for cleaning;

8 - screws for removing ash;

9 - removable tank for ash;

10 - combustion chamber made of stainless steel;

11 - heat exchanger having a return water temperature controller;

12 - heat exchanger with built-in automatic cleaning function;

13 - oxygen sensor in outgoing flue gases;

14 - smoke exhauster;

15 - mixer valve;

16 - circulation pumping unit;

17 - valve for switching between water supply / heating systems;

18 - outlet to the heating system;

19 - outlet to the water supply system;

20 - outlet from heating / water supply systems;

21 - air supply for combustion.

The pellet boiler works according to the following principle. The granules are poured into the fuel tank, which, with the help of screws, enter the boiler furnace. Pellets burn out, emit thermal energy, which is used to heat the coolant in the heating system. The products of combustion in the furnace rise and transfer heat through the walls of the heat exchanger, after which they exit in a cooled form through the chimney. The heat exchanger is made of steel (provides strength, but needs anti-corrosion treatment) and cast iron (does not rust, but is not resistant to thermal shocks).

Boilers on pellets have a high efficiency - 70-90% depending on the class of equipment - medium / premium. The service life of the heating device is 10-50 years

Advantages and disadvantages of pellet boilers

Automatic pellet boilers are characterized by the following advantages:

- Economy of consumed fuel. Pressed fuel burns without residue. The consumption of pellets depends on the quality/composition of the pellets and the class of the boiler. By weight, the heating device consumes 2 times less fuel than a wood-burning boiler.

- Energy independence. Boilers can work without electricity. Some models are equipped with electrical equipment, but in most cases such units are completely non-volatile.

- Fuel storage requires less space.

- It is enough to clean the boiler furnace once a month. In comparison, a wood-burning boiler needs to be cleaned almost every day.

- Pellets are cheaper than firewood.

- Pellet boilers are environmentally friendly equipment, as they operate on natural fuel, burning wood without residue.

- Pellet equipment is cheaper than gas and electric boilers.

- The boiler can function without human intervention for a week.

- You can install an additional heating water supply.

The funds spent on the purchase and installation of a pellet boiler will pay off in 1-2 years. Subsequent fuel savings in the tens of thousands

The inconvenience of using pellet boilers is that periodically they need to be loaded with pellets supplied in bags, as well as cleaning the heat exchanger and ash collector.

Important! Despite the fact that the construction of a chimney is not required when installing a pellet boiler, it is still necessary to equip a hole in the wall or ceiling. It will be needed if there is no electricity in the house and the fan stops

Types of pellet boilers

Pellet heating equipment can be conditionally divided into three groups:

- Actually pellet boilers use only wood chip pellets as fuel. In such a device, retort-type burners are used.

- Conditionally combined boilers operate on biogranules, but if necessary, firewood and briquettes can be used as a “reserve” raw material. Burning with alternative fuel can be carried out for a short time. In such boilers, the firebox is arranged in a special way - the regular grate can be removed.

- Universal coppers work at any solid fuel. Usually the unit has several combustion chambers (separate for each energy carrier). To change the fuel, it is enough to remove the pellet burner, and the device is ready to work on traditional solid fuel.

According to the type of pellet burner, boilers are divided into two types: retort and torch type. Flare type burners are used in combined boilers and have the following advantages:

- simplicity and versatility of installation in different types of boilers;

- device reliability.

Flare burners are characterized by lower power compared to retort ones, and, accordingly, have lower efficiency.

Characteristics of retort-type pellet boilers:

- the possibility of thermoregulation;

- high power;

- use only pellet granules, which it is desirable to stock up immediately for the whole season.

Consider some models of pellet boilers from different manufacturers.

South Korean firm Kiturami produces two popular models of pellet boilers: Kiturami KRP 20-A and Kiturami Premium. The heating equipment of this company has the following characteristics:

- boilers have a fuel overflow protection mechanism;

- condensation does not form on the walls of the heat exchanger, due to the exact matching of the operating time of the circulation pump and the burner;

- availability of an automatic grate cleaning system;

- an additional solenoid valve ensures a high level of fire safety.

Distinctive features of Kiturami Premium:

- efficiency level - 94%;

- improved bunker;

- electronic burner control;

- the fuel bunker holds 160 kg;

- pellet consumption - 5.5 kg/h;

- warranty period - 2 years;

- cost - about 4300 US dollars.

Kiturami KRP 20-A has the following features:

- the boiler is used not only for heating, but also to provide the house with hot water;

- automatic dosing of fuel;

- ease of installation and cleaning of equipment from ash;

- built-in freeze/overheat protection;

- boiler power - 24 kW;

- capacity of the hopper for pellets - 160 kg;

- fuel consumption - 5.5 kg / h;

- cost - 3600 US dollars.

domestic company "Teplodar" produces the boiler "Cooper OK-15", which has the following characteristics:

- use of different fuels (coal, firewood, pellets);

- you can install a gas burner;

- fuel ignition - mechanical;

- Efficiency reaches - 94%;

- device power -15 kW;

- capacity of the bunker for fuel loading - 200 l;

- fuel consumption -1-5 kg/h;

- boiler cost - 1100 USD.

When choosing a pellet boiler, you can follow these recommendations:

- An important selection criterion is the power of the boiler and the heat loss of the house. You can follow the formula: 1 kWh of heat = 10 sq.m.

- Decide on the type of pellet boiler - specialized (furnace exclusively with pellets) or universal.

- When choosing a pellet boiler, it is necessary to ensure a supply of pellets for the entire heating season.

- Before purchasing the boiler, it is necessary to study the operation of the control unit. It is important that the control system is docked with automation. Not all models of pellet boilers have inputs for connecting additional sensors or external control systems.

- It is necessary to make sure that the company's service department has all the necessary spare parts for the boiler model being purchased. The company must issue a warranty certificate and quality certificate for the pellet boiler.

You can make a pellet boiler with your own hands. The network has a lot of information on how to calculate, design and assemble heating in a house. But is it worth it? Pellet boiler - a highly efficient device that guarantees uninterrupted and safe heating

Installation of pellet boilers

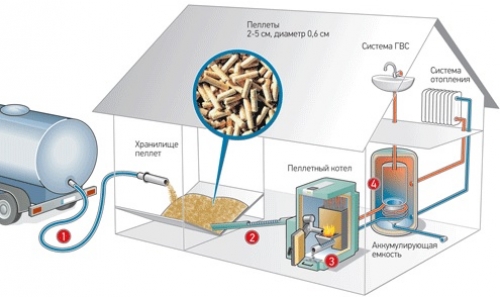

Boiler connection diagram

The heating / hot water supply system of the house with the help of a pellet boiler provides for the installation of an accumulation tank.

Pellet boiler: connection diagram

1 - Delivery of pellets to the storage. The volume of the storage bin is about 4.5 sq.m. - this is enough to heat one private house per family.

2 - Connecting the storage to the pellet boiler. Giving of granules happens automatically.

3 - Connecting the boiler to an intermediate storage tank.

4 - Circulation of the coolant through the heating and hot water system.

Requirements for the room for the installation of the boiler

For the installation of pellet boilers, the following conditions must be met:

- The optimal base for the boiler is a concrete screed, about 5-10 cm high. Such a floor facilitates cleaning and maintenance of the boiler.

- For heating a small house, a boiler can be installed in the house itself. If there is not enough space for equipment, then the boiler is placed in a special boiler room or in a garage next to a residential building. In this case, the laying of pipes from the boiler to the house is carried out underground at a depth below the freezing level of the soil. The pipe must have good thermal insulation.

- An important condition for the normal operation of the boiler is the evenness of the base. The device provides for a vertical position.

- The temperature in the room should not be lower than +10 С°, humidity should be about 40%.

- Near the device it is necessary to equip a separate place for storing wood pellets.

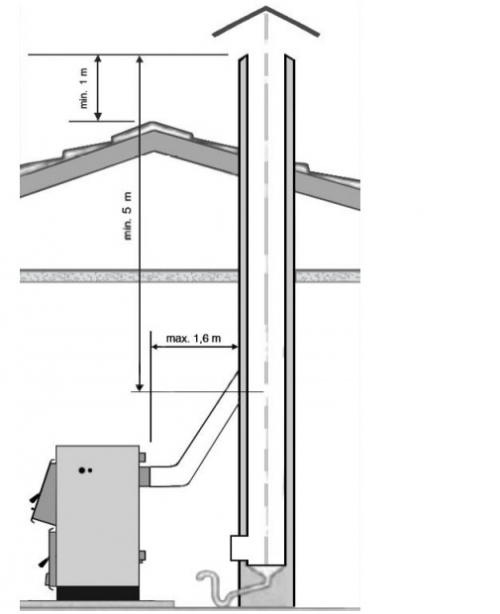

- The boiler room must be ventilated. The chimney of the boiler is discharged through the roof of the building.

Installation steps

Consider step by step how to install a pellet boiler:

Important! It is better to entrust the collection, installation, adjustment of a pellet boiler to a technician specializing in such operations.

Commissioning the boiler

Before starting the automatic pellet boiler, check:

- compliance of the heating system with the project;

- tightness of the chimney, bunker and boiler;

- whether the heating system is filled, the pressure in the system;

- performance of control devices.

The sequence of switching on the pellet boiler:

- Fill the bunker with fuel.

- Check the water pressure level in the system.

- Open the smoke damper.

- Ignition on burners - carried out through the control panel or manually.

The boiler is switched off after the remaining fuel burns out. Afterburning can be observed through small holes in the damper of the upper door of the device. At the end of the heating season, the boiler must be cleaned of soot / ash, and the burner socket must be disconnected from the electrical network.

Operation of pellet boilers: video