Long-burning coal and wood fired boilers are a real achievement in the field of energy efficiency. These solid fuel units are a heating device made of cast iron or steel, designed to heat various premises (industrial, residential, administrative) and provide hot water.

Scheme of one of the types of long-burning boilers on coal. It uses the principle of lower combustion (click on the picture to enlarge it)

To understand the essence of the operation of a long-burning boiler, take a thin wood chip, set it on fire and turn it vertically, with the fire up. The fire will go down slowly, and the burning time will approximately double compared to burning in any other position. It is this principle that formed the basis of the operation of this equipment.

The following advantages of solid fuel boilers of this type can be distinguished:

- Economical fuel consumption. Resources burn slowly and in layers, burning from the initial load to 98%.

- Requires minimal human intervention and infrequent maintenance.

- The boiler does not overheat thanks to the automation that controls the combustion process. The design also contributes to a uniform temperature distribution inside the firebox, which ensures its reliability and trouble-free operation.

- High efficiency due to the location of the heat exchanger over the entire inner surface of the combustion chamber. Moreover, the water circuit itself is designed in such a way as to exclude the formation of stagnant places and create a directed flow of water. This ensures efficient heat removal and rapid heating of the coolant.

- Easy to operate, no smoke, odors, dust.

- Safety of technology and environmental friendliness of materials, low noise level.

Like any other device, a long-term combustion boiler has disadvantages:

- High cost due to equipping with an automatic control system. But these costs will pay off in a few years due to fuel savings.

- Large overall dimensions and heavy weight. This is due to the significant volume of the combustion chamber and the usually considerable dimensions of the water circuit.

- There is no possibility of manual control of the process (deceleration or, conversely, acceleration) during the combustion cycle, since the process is fully controlled by the automation system.

- Energy dependence. Almost all systems today operate using a circulation pump. And without power supply it simply does not work. Most of the boilers are also controlled by automation, so a backup power supply is required to provide heat, which can be performed with batteries connected to them. This, of course, reduces the dependence of the system on the availability of electricity, but it costs decent money.

Use a pump to forcefully control the circulation of the coolant, it will increase the efficiency of the entire heating system.

It must be said that many solid fuel boilers for long burning can work both on and on wood. When buying such a boiler, it is worth remembering that one of the types of fuel still remains the main one. And the equipment will work with maximum efficiency on this type of fuel: it was designed for it. Therefore, be sure to specify what the unit you have chosen “prefers”, so that it does not turn out that you have a lot, and you bought a boiler designed for coal. It will work, but you will often have to be near the boiler: the furnace and coal cats are smaller in size, so you won’t be able to put a lot of firewood there, therefore, they will burn out quickly and you will have to reload fuel.

Overview of long-burning boilers Energy TT

The units are produced by the Kharkiv Engineering and Technical Center for Heating Equipment "Energy +" with a power of 6–60 kW, various volumes of the fuel bunker, dimensions, weight and estimated dimensions of the heated area .

Coal-fired long-burning boilers "Energiya TT"

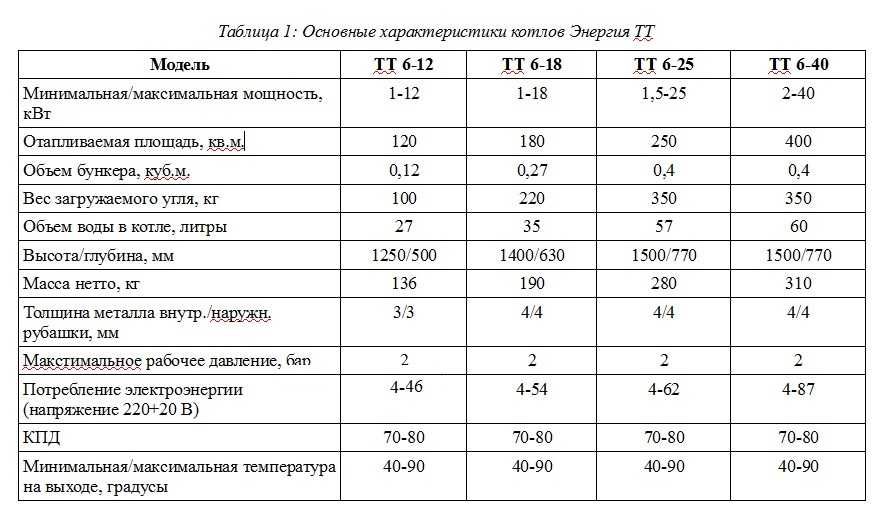

The main characteristics of the boilers Energia HP 6–12 kW, HP 6–18 kW, HP 6–25 kW, HP 6–40 kW are presented in the table .

Characteristics of coal-fired boilers "Energy TT" of different capacities (click to enlarge)

Important! In order to increase the heating capacity for heating larger rooms, it is necessary to connect several hot water boilers in parallel, then they will be able to heat the required space in total.

Heating devices Energy TT with a single load of coal can work up to 20 days. This indicator is influenced by the thermal insulation of the room, the loss and amount of coolant, the period of use (off-season or heating), a competent calculation of the power of the unit and what quality the fuel is used. Let's take a closer look at the last factor.

What is the best coal to use?

Coal for a long-burning boiler Energy TT, it is preferable to use anthracite ("A"), acceptable - fine ("M", fraction size up to 25 mm), walnut ("O", fraction 25–50 mm) with a moisture content of not more than 20%.

For maximum efficiency, Energia boilers need to be fired with anthracite of medium fractions

Based on the operating experience and feedback from the owners, in order to save on the purchase of fuel and not damage the boiler, you can mix fine coal with coarse coal, so it will fill the bunker more densely, therefore, ensuring reliable and long-term operation of the unit.

How to melt

First, 3-4 kg of wood logs (necessarily dry) are placed in the bunker, then partial or full loading of coal is carried out through the upper chamber. In order to prevent fine coal from waking up in the ash pan, you must first pour a layer of coarse fraction, and add fine fraction on top.

The next step is to set the necessary parameters (temperature, smoke exhauster power), and then the boiler is ignited through the ash pan. After the unit switches to the operating mode, coal combustion will occur slowly, in layers and in the direction from bottom to top. The supply of air and the removal of gases occurs according to the principle of ejection, that is, the air pushes the gases in the right direction. The design features of Energia TT make it possible to load coal into the bunker directly during operation, as well as to remove ash simultaneously with fuel loading.

We invite you to watch the launch and entry into the operating mode of the long-burning boiler Energia TT on this video .

Operating experience and feedback from the owners of boilers Energy TT

Analyzing the reviews, we can highlight the following points:

- Convenient and clear design.

- Significant savings in coal consumption compared to conventional boilers. One of the owners previously had an ordinary boiler and during the heating period (4 months) spent 15 tons on heating his house, and with the Energy TT 25 kW boiler - 9.8 tons.

- When using anthracite, there is a minimum of deposits, there is no need for frequent cleaning.

- There are complaints about a slight release of smoke and dust when loading fuel.

- Many people note a constant and comfortable temperature in the rooms and little fuss associated with servicing the unit.

- According to reviews, a single laying of coal is enough for 4–6 days (a boiler with a capacity of 40 kW), and according to some sources, up to 8–9 days (a unit of 15 kW), while the outlet temperature is 52–54 ° C, and in rooms 25–26 °C These are very respectable figures.

- Some owners, who were previously skeptical about coal, write that in practice everything turned out differently: it is convenient to buy coal in bags of 50 kg, it does not get wet, and does not emit unpleasant odors.

- There are no complaints about the automatics of the boilers, which indirectly confirms their quality.

In general, the reviews are positive. These boilers are a worthy choice in modern conditions, their price depends on the characteristics of a particular unit. For example, a 12 kW Energia TT boiler will cost about 45,000 rubles, 18 kW - 60,000 rubles, 25 kW - 70,000 rubles, 40 kW - 77,000 rubles, 60 kW - 93,000 rubles. The manufacturer provides a 60-month warranty period for the boiler body, and 30 months for the automation and fan of the smoke exhauster.