For those who decide to switch to heating with pellets, the question has already been resolved - why they do it. Now it is important for such an owner to understand the principle of operation of a pellet boiler, what is the connection scheme for a pellet boiler and how pellet boilers are installed in new or existing heating systems.

The very fact that a person has to install just such a heat generator that burns pellets usually indicates that the main gas is not available, and if there is no night or rural tariff, it is too expensive to heat with an electric boiler.

Otherwise, the installation of pellet boilers looks like just a whim, a desire to “play around” with a new expensive toy.

Because if you have access to mains gas at a reasonable price or you can heat your house with electricity at a price of 0.85 rubles per kilowatt, then heating with pellets at a price of 2 rubles per kilowatt looks, to put it mildly, incomprehensible.

But if you do not have either one or the other, then connecting a pellet boiler to your heating system is just a matter of time. Because in the absence of cheap gas and cheap electricity, only automated and capable of providing the house with normal heat in batteries and hot water in the tap.

Let us briefly consider the device of a pellet boiler, its principle of operation and connection diagram.

The principle of operation of the pellet boiler

The basic principle of operation of a pellet boiler is the metered supply of fuel to the combustion chamber in the amount that is needed to obtain a given amount of thermal energy at a given moment.

Each of the above types of burners needs a separate description, therefore each of them has a separate article - see them on the website in the "Burners for boilers" section.

As for the boilers equipped with burners with forced feeding of pellets, fuel is supplied to them by an auger or pneumatic supply from the hopper to the burner in precisely measured portions by the controller. The size of the portions depends on the temperature that is required to be maintained at the moment in the house and on the temperature of the outdoor air.

The burner fan forces air into the combustion zone. The amount of air is also calculated by the controller.

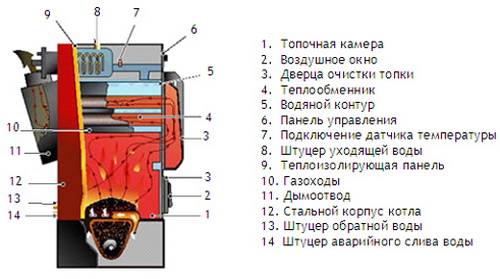

The heat from the burnt pellets is removed by a tubular, plate or fire tube boiler heat exchanger, depending on the design of its furnace. use vertical tubular heat exchangers and horizontal multi-pass heat exchangers.

In general, the concept of “the best pellet boiler” depends on many factors, and in different conditions, one or another heat generator will be the best boiler.

For example, in the absence of electricity, the best boiler would be a non-volatile pellet boiler Pelletron. Under these conditions, only the simplest pellet boiler scheme will work.

And in conditions of strict fuel economy, the best pellet boiler will be an expensive boiler with good automation, which allows you to fine-tune the burning of pellets.

After the flue gases have given up their heat to the heat exchanger, they are discharged into the chimney. A chimney for a pellet boiler is a topic for a separate discussion, see also it on our website.

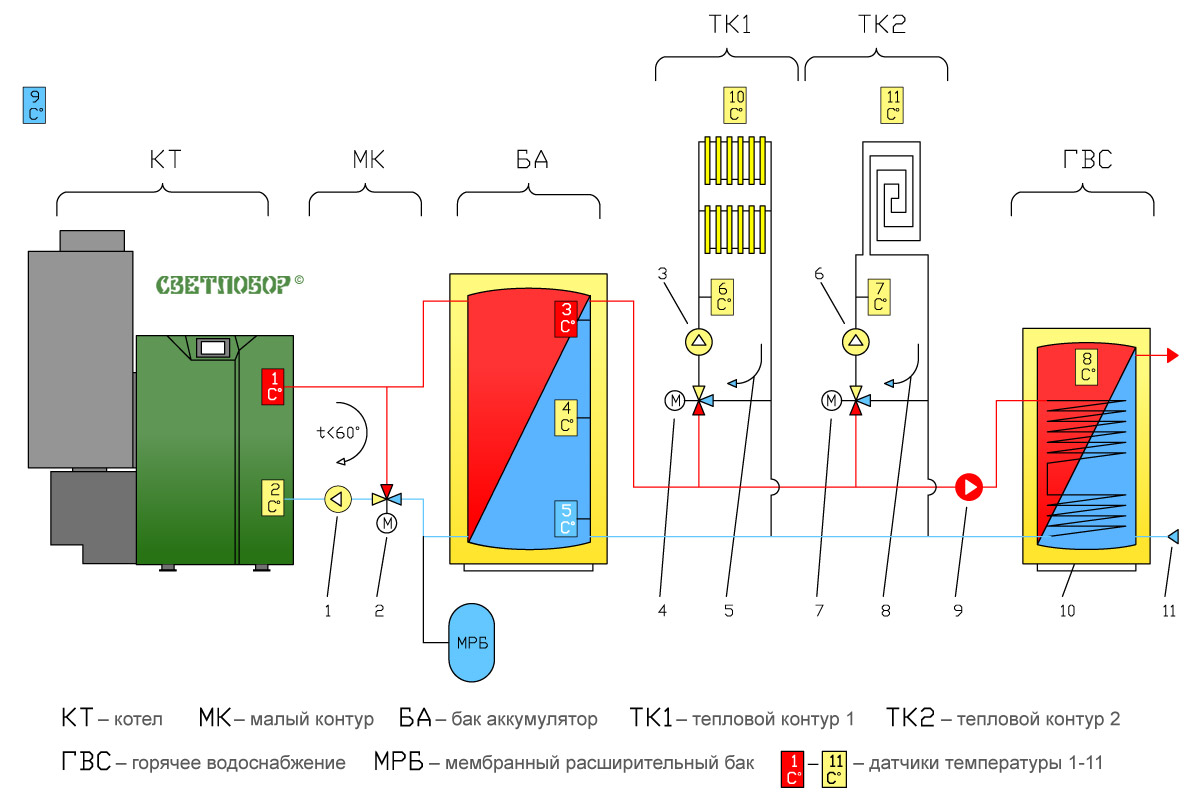

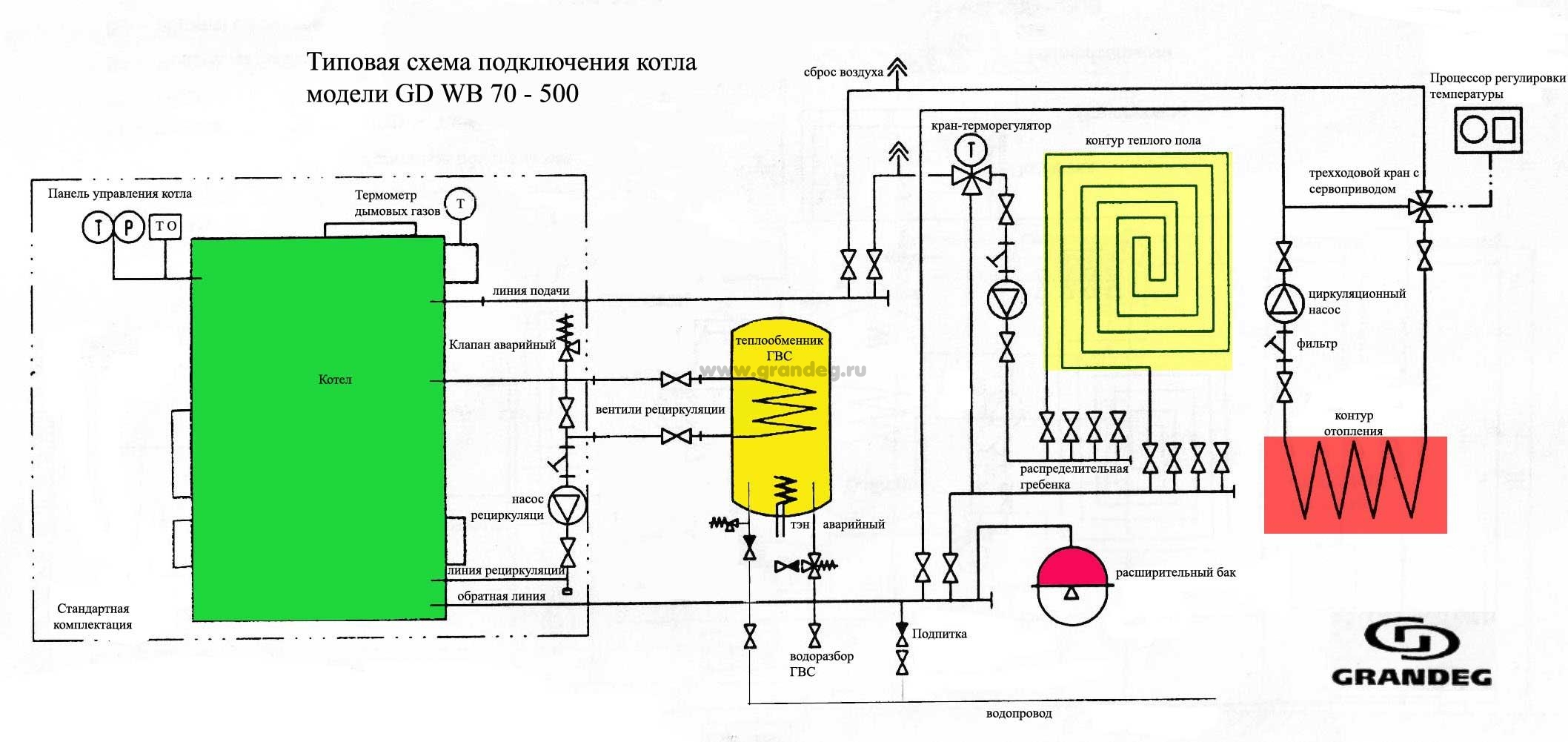

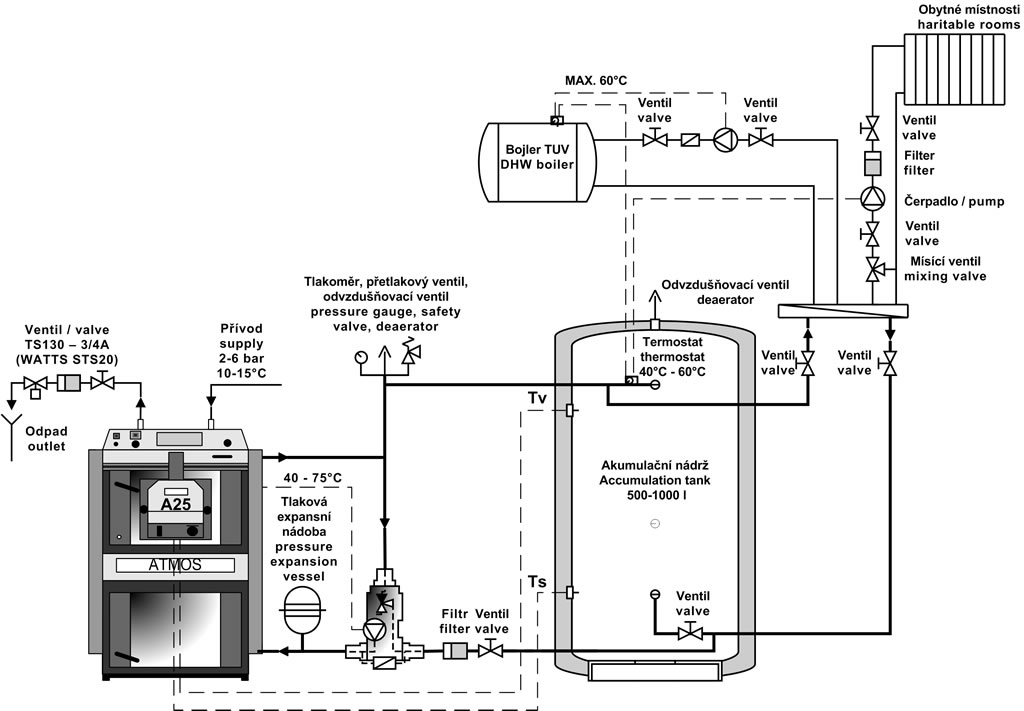

Pellet boiler connection diagram

The scheme for connecting a pellet boiler to a home heating system is identical to the scheme for connecting any heat generator, whether it is a diesel fuel boiler.

The lower pipe of the boiler cuts into the return, the upper pipe cuts into the supply. The combustion of pellets in the boiler burner is strictly controlled by two factors:

- auger fuel supply

- air supply by a fan.

Therefore, overheating of the boiler in a normal situation is impossible. This means that there is no need to tie the boiler supply with metal. The scheme of a pellet boiler with polypropylene or metal-plastic pipes has worked great for many owners for many years.

And for emergency situations caused by accidents in power lines or a failure of the boiler controller, it is worthwhile to provide an emergency shutdown scheme for the fuel and air supply to the boiler combustion chamber. The one that at the time of the accident will be in the boiler furnace is no longer able to cause overheating of the coolant in the heating system.

Naturally, a safety group with a pressure gauge and an emergency valve must be on the boiler supply.

With such simplicity of strapping, the installation of pellet boilers can be carried out not by a specialized organization, but by any construction organization with a license.

Just do not trust the installation of pellet boilers to the first comers. This is a thermal device designed for burning wood fuel, it is a source of increased fire hazard. And therefore, they may be able to install a pellet boiler. But to set it up and ensure fire safety is unlikely.

Installation of pellet boilers - some features

Most pellet boilers are made using boiler steel, the share of cast iron boilers on the market is small. This is due to the fact that the high combustion temperature of the pellets is localized either in the flame of the blast burner or in the cup of the retort burner. Therefore, there is no need to make the entire boiler out of cast iron, as is the case with coal or wood boilers.

This means that a separate foundation or reinforced floors are not needed to install a pellet boiler. An ordinary boiler with a capacity of 20-40 kilowatts weighs from 150 to 300 kilograms, which allows it to be installed on the floor of the most ordinary boiler room, without any reinforcement.

If you mount a large volume hopper for 0.5 - 1.5 tons of pellets to the boiler, then you will have to make a reinforced base under it.

Further, since there is very, very little ash produced, there is no need to frequently clean the boiler and remove the ash. It is enough to buy a pellet boiler with a large ash pan and clean the boiler once a week. Some comrades come to their boiler once a month, but this, I think, is too much. The boiler must be monitored and serviced.

The Polish company Kostrzewa has been producing solid fuel boilers for over 30 years. However, in Russia she became known only when she became ...

Floor cast-iron gas boilers are most often installed in private homes. Their use allows you to save gas. Which floor boiler to choose and ...